Are you sure you are Insured?

Years of faithful insurance premiums can prove valueless in the absence of a Certificate of Conformity (CoC). It is a startling fact that you stand tolose hefty amounts of money that were meant to be an “insurance” on your assets. Insurance companies will not cough-up if you cannot present a valid CoC when making a claim. Can you afford to lose all your assets and have your insurance repudiated?

A vast majority of South African citizens are moving towards the use of Gas Appliances due to the increasing cost of electricity and possible outages. However, most users are unaware of the specific regulations and safety standards with which they must comply when getting gas equipment installed in their households. Overlooking these regulations can be detrimental in many ways.

According to the Pressure Equipment Regulations (PER), all Natural Gas and Liquefied Petroleum Gas appliances and equipment should meet the specified standards to ensure safety. These regulations set out the requirements regarding the design, manufacture, operation, repair, modification, maintenance, inspection and testing of pressure equipment. In terms of the Occupational Health and Safety Act, 1993, the PER also requires persons handling the installation of any gas systems to undergo specific training and to be registered with the South African Qualification and Certification Committee – Gas (SAQCC Gas). The Registered Gas Practitioner must issue a Certificate of Conformity (CoC) for any equipment they install.

What is a CERTIFICATE OF CONFORMITY?

A Certificate of Conformity (CoC) for Gas installations is a legal document which must be obtained whenever a gas system is installed, modified or repaired and should be retained for possible future requirement.

Only Registered Practitioners may issue a CoC and a complete list of these practitioners can be found on: www.saqccgas.co.za

COC and Insurance

Most People are oblivious to the importance of holding a CoC for every Gas installation on their properties, this includes air conditioning and refrigeration units – the importance is generally realised when it is too late. It is usual for people to get insurance cover for their properties and assets, however, it is a staggering truth that owners could be paying insurance premiums for years and end up receiving no cover in the occurrence of an incident or accident involving gas. Should there be no valid Certificate of Conformity, many insurance companies will not accept liability for costs of damage caused to property or assets. The loss and damage suffered by an owner/user due to a Gas installation for which a valid CoC has not been issued, falls entirely on the owner. Regardless of cost of reparation, the insurance will most likely not cover it.

“The majority of insurance companies would require this certificate to prove that the installation was safe and had been serviced regularly.” Lanice Steward- managing director of Knight Frank Anne Porter

The honeymoon is over – All aboard?

The gas industry latches on to the Occupational Health and Safety Act which is central to safety and technical compliance impacting people, equipment, buildings, and the environment.

The Pressure Equipment Regulations (PER) gazetted in 2009, which govern the installation, design, manufacture, operation, repair, modification, maintenance, inspection and testing of pressure equipment have been in existence for a decade now. The South African Qualifications and Certifications Committee of Gas (SAQCC Gas) is mandated by the Department of Employment and Labour (DEL) to ensure that everyone practicing in the Gas Industry adheres to these regulations. SAQCC Gas ensures that only skilled and competent individuals practice. It has been more than a decade, this is a long enough period to have had everyone in the industry on the compliance wagon. However, this has not entirely been the case.

How did Industry position itself within the required legislative framework over the period and how did industryshape on the compliance dashboard?

The transpiring factsare that theresponse is not as simple as may seem, a few reasons being:

- Not all get on the compliance wagon at the same time?

- Some schedule compliance over time and succeed, some refuse to acknowledge new legislation, others just plainly ignore?

- Others struggle to get their heads around the requirements of legislation, others just don’t care?

Undoubtedly there are many businesses seeking to do the right things, right? Kudo’sto all and thank you!

On the other hand, the reality is the honeymoon is over. Legislation is here to stay and compliance thereto is non-negotiable. SAQCC Gas together will the DEL will be intensifying the regulation of the industry, incompetence is inexcusable and will not be tolerated! SAQCC Gas looks to ensure that all Gas Practitioners adhere fully to the PER, with absolutely no defects, while the DEL will ensure that anyone operating illegally (not registered with SAQCC Gas) is held accountable and removed from the industry.

Once legislation is promulgated there is only one way forward. So why the non-compliance? ‘’I didn’t know’’ is not an excuse anymore. How do companies mitigate risks being non-compliant? Insurance houses are always looking for loopholes and not to pay so compliance needs to be managed and ensured. Not forgetting companies’ section 16 and GMR 2 appointee’s accountability,liability, roles, and responsibilities.

What needs to be done is to enable an ongoing supportive and corrective environment through education and awareness through Stakeholders like Department of Employment and Labour, Manufacturers, Importers, Suppliers, Users, Gas Practitioners, and the SAQCC Gas.

Another posing question, is what should be done to those that do not comply? After a decade, one cannot deny the existence of legislation when working in the pressure equipment environment. Simply put, apply corrective action or take the transgressors to task.

The Gate Keepers responsible to fulfil significant roles in ensuring compliance with gas systems are Users, Importers and Suppliers of equipment, Gas Practitioners, Gas Suppliers among others. Nonetheless, Users, need to be resilient as to compliance from all who provide services, after all, the buck stops with them.Gas suppliers, especially, should be more stringent by ensuring downstream operations are compliant prior to providing gas to User’s gas system.

It’s time to take stock, get one’s house in order, and ensure a safer place to work and live in. All aboard?

To report non-compliance click here.

Instilling Gas Compliance in Cape Town

To expand industry compliance in South Africa, the South African Qualifications and Certifications Committee of Gas (SAQCC Gas) is embarking on a Roadshow campaign. The objective is to reach everyone practising in the Gas industry and the end-user who utilises gas equipment. SAQCC Gas has been mandated by the South African Department of Employment and Labour (DEL) to ensure everyone operating in the Gas Industry has been trained and is qualified to safely complete gas-related work. SAQCC Gas registers all qualified Gas Practitioners, qualifying them as legal and compliant industry players.

Did you know? SAQCC Gas is made up of four associations that regulate different types of gas, these associations are; LPGSASA, SACGA, SARACCA, and SAGA

The Pressure Equipment Regulations (PER) gazetted in 2009, regulates the installation, design, manufacture, operation, repair, modification, maintenance, inspection and testing of pressure equipment. These regulations have been in existence for a decade now. Despite this fact, there are still reports of illegal Gas installations completed by unskilled and non-registered individuals. Such installations are hazardous and unsafe and place the User at risk.

On the 25th of February 2020, SAQCC Gas hosted a session in Cape Town. This has been one of the most successful sessions since the Roadshow campaign began. The actual number of attendees by far surpassed the anticipated number. There is a great need to educate and enforce gas compliance and related safety standards. The event was attended by the Department of Employment and Labour officials; Director of Electrical and Mechanical Engineering, Mr Malatse and Deputy Director of Electrical and Mechanical Engineering, Matlala Sathekge.

“The Western Cape Province has a high number of reported gas-related accidents mostly within the LPG sector .”

Matlala Sathekge

The Cape Town session was attended by a variety of persons, amongst others were; older knowledgeable Gas Practitioners, newly registered Gas Practitioners, end-users and Fire Department officials. Director of Electrical and Mechanical Engineering Jakes Malatse opened the floor by introducing the PER, on which all other practices in the Gas industry are required to adhere to. One of the topics discussed was the importance of keeping up with the regulations. In his presentation, CEO of the Southern African Gas Association (SAGA), Roy Lubbe, explained the difference between the old Vessels Under Pressure (VUP) regulations which were replaced by the PER in 2009. Also presented a narrative and various applications in applying the regulations and standards pre and post 2009. This was vital content for the more senior Gas Practitioners who might have previously adhered to the VUP and were now required to align their work to the PER. This emphasised the importance of keeping up with compliance regardless of how experienced the Gas Practitioner might be.

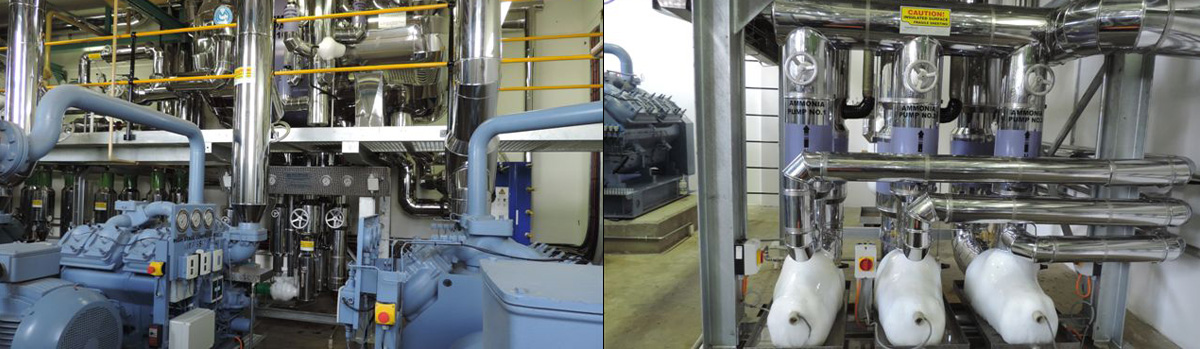

The Director of the South Africa Refrigeration and Air-Conditioning Contractors Association (SARACCA), Barney Richardson, spoke about the different registration categories, this was a very interactive session as there seemed to be a lot of misconceptions regarding the margins of each category. The Liquefied Petroleum Gas Safety Association of South Africa (LPGSASA) was represented by Zandile Msholoqa the association’s compliance officer is. One of the reasons that lead to non-compliance is Gas Practitioners practising out of their registration scope, Ms Msholoqa elaborated on the three basic training courses in the LPG industry: domestic, commercial and industrial. The objective of the Roadshow is to ensure registered Gas Practitioners remain compliant, to help non-compliant individuals hop on the compliance wagon and to educate the end-user on how to safely benefit from their gas equipment. This was indeed a successful roadshow!

To report a rouge installer click here.